Chitra Gidc, Bhavnagar, Gujarat

- GST NO. : 24AAHFS9441A1ZE

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

Preferred Buyer From

| Location | Worldwide |

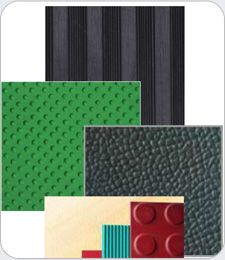

DESCRIPTION : NR / SBR blend rubber sheets / rolls are used in the commercial and industrial applications. This specifically designed rubber material is long-lasting that is suitable for operational use which provides excellent mechanical properties like high resilience, low compression set, high resistance to cut, tear & abrasion & also offers resistance to many acids, alkalis & salts. The operation temperature range is (-20°C to +80°C). It is available in wide range of hardness from 40 Shore A to 80 Shore A. It has very good physical properties like Tensile strength, wear & tear properties, Abrasion resistance.

APPLICATIONS : NR / SBR Rubber sheets / rolls are used for wide range of applications like skirt board, bridge bearing, gasket for high pressure packing, heavy weight machinery packing, Para-quality for sand/shot blasting machinery & used as shock absorber. NR / SBR Rubber sheets/rolls can be used as shelf liner; workstation table liner and work area rubber lining that can withst and moderate chemicals & alkaline solutions. These sheets can also be used for anti abrasion lining for material handling machinery in mines alike industries.

PROPERTY : Excellent resistance to inorganic chemicals, water, air & heat up to 80°C. Poor resistance to Ozone, UV, Sunlight, oil & solvents & organic chemicals.

STORAGE OF PRODUCTS

Do not expose rubber sheet to direct sunlight, sheets away from heat source, preferably in dark, air ventilated room will help give longer life & optimum properties

Do not remove polythene packing before use to prevent it from exposure of atmospheric oxygen, ozone & polluted air. Do not store rubber sheet rolls in open, even after covering it with tarpaulin to protect from air & rain. Always keep rolls in vertical position ONLY

Keep rolls away from solvent, oil & fuel storage. Do not use hooks while loading/unloading the rolls. Inspect sheet for smooth surface & hardness (with rubber hardness tester).

Technical Specifications

| GRADES | DENSITY (g/cc) | HARDNESS (SH–A) | TENSILE (Kg/cm2) | Elongation (%) |

| BNS-1240 | 1.2 | 40 | 80 | 600 |

| BNS-1345 | 1.3 | 45 | 90 | 500 |

| BNS-1450 | 1.4 | 50 | 70 | 450 |

| BNS-1565 | 1.5 | 65 | 60 | 400 |

| BNS-1670 | 1.6 | 70 | 50 | 300 |

PRODUCT DIMENSIONS (Rotocure Finish)

| SIZE (Mtrs) | THICKNESS (MM) |

| 1.2 x 10, 20, 30 | 3 to 12 |

| Finish | Smooth / Texture Impression |

PRODUCT DIMENSIONS (Plate Finish)

| SIZE (Mtrs) | THICKNESS (MM) |

| 1.2 x 2.4 | 3 to 25 |

| 1.0 x 2.0 | 3 to 25 |

MANUFACTURING TOLERANCES

| THICKNESS | WIDTH | LENGTH | HARDNESS | DENSITY |

| + / - 0.3mm or 10% whichever is higher | + / - 2% | + / - 5% | + / - 5 | + / - 0.05 |

Looking for "NR/SBR Rubber Sheets and Rolls" ?

Explore More Products

Our Blogs